Why Energy Efficiency Must Be Central to Decarbonising Diesel-Dependent Equipment Sectors

January 5, 2026

Australia’s construction, infrastructure, and off-road industries rely heavily on diesel fuel, which contributes significantly to the nation’s emissions. The government’s fuel tax credit scheme, designed to support these sectors, now costs over $15 billion each year. While progress is being made with electrification pilots, low-carbon fuel experiments, and efforts to reduce carbon in building materials, one crucial approach is being overlooked: making better use of the fuel we already consume. Without focusing on this, we’re wasting valuable resources and slowing our journey to net zero emissions.

The Challenge: Diesel’s Stubborn Grip on Construction

According to Infrastructure Australia’s 2024 projections, the construction sector could produce between 37 and 64 million tonnes of carbon dioxide equivalent (Mt CO₂e) annually through 2026–27. This comes from on-site machinery like dozers, loaders, and excavators, which work tirelessly during digging, pouring, and grinding phases, alongside the materials used. Estimates suggest these activities burn 7 to 10 billion liters of diesel each year, a figure subsidized by tax credits but largely ignored in plans to cut emissions.

The Efficiency Advantage: Making Every Drop Count

Upgrading to modern engines can transform how we use diesel, offering clear benefits for businesses and the environment. Consider the following advantages:

- Significant Fuel Savings: Engines meeting EU Stage V or US Tier 4 Final standards reduce fuel consumption by 20 to 35 percent, thanks to simpler improvements like better combustion. This means less fuel is needed for the same work, cutting costs over time.

- Quick Return on Investment: Switching from older Tier 2 or 3 engines—some still imported—can save enough money to cover upgrade costs in just 1 to 2 years, making it a practical choice for companies.

- Amplified Impact with Alternatives: When paired with a 20 percent cut from biodiesel, the savings grow because the engine uses 30 percent less fuel to begin with, making greener fuels more effective.

This approach provides a practical, no-regrets foundation for deeper emissions reductions, proving efficiency is a win-win strategy.

Additional Co-Benefits: Cleaner Air and Healthier Communities

Beyond cutting carbon emissions, newer standards also reduce harmful pollutants like PM2.5 and nitrogen oxides (NOx), tiny particles and gases that can penetrate deep into the lungs and are linked to serious health issues such as lung cancer, heart disease, and respiratory problems. Construction workers face higher exposure on job sites, and nearby urban communities are affected too, especially in densely populated areas. In response, London has introduced strict rules, mandating Stage IV engines by 2025 and upgrading to Stage V by 2030 to protect public health. In Australia, Western Australia has guidelines to limit diesel exposure in mining operations, but no similar nationwide rules exist for construction—making the case for cleaner, more efficient equipment even stronger.

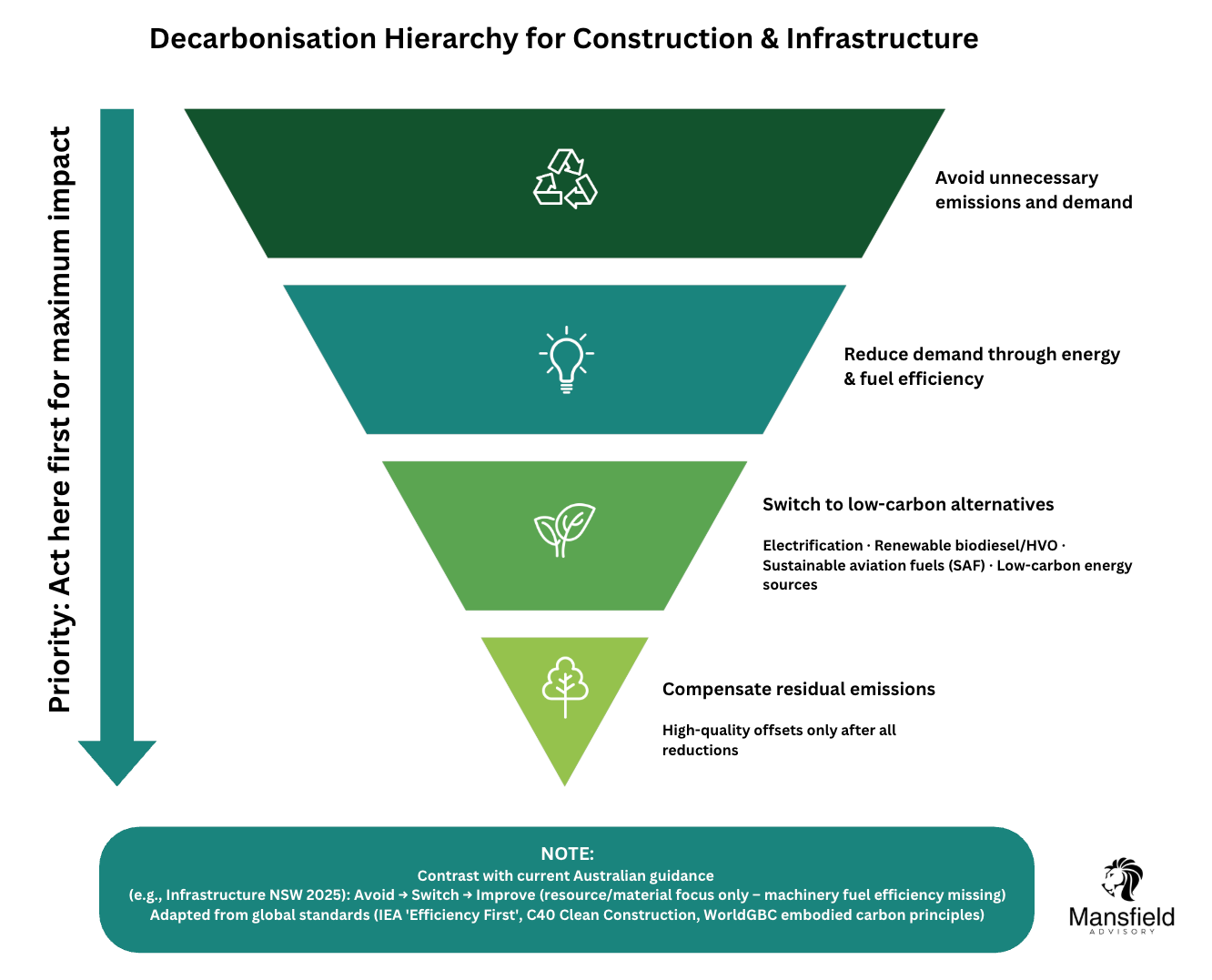

A Proven Hierarchy We’re Missing

Around the world, experts follow a clear decarbonisation hierarchy to tackle emissions effectively (see Figure 1). It starts with avoiding unnecessary emissions through smart design and reuse, such as planning projects to minimise waste. Next, it emphasises reducing fuel use by upgrading machinery, like adopting Stage V engines that save 20–35 percent. Then, it suggests switching to low-carbon alternatives such as electrification or sustainable fuels. Finally, it allows for compensating any remaining emissions with high-quality offsets. This approach, supported by the International Energy Agency, C40 Cities, and the World Green Building Council, ensures the best results. Unfortunately, Australia often jumps straight to switching fuels without prioritising reductions, missing a key opportunity.

Figure 1: Decarbonisation Hierarchy for Construction & Infrastructure. A prioritised approach to emissions reduction, highlighting efficiency as a critical step in reducing demand for fuels.

Global Benchmarks: Efficiency as a Core Strategy Elsewhere

Internationally, efficiency is proving its worth in meaningful ways. The GlobalABC’s 2024–2025 Report highlights how mandatory codes and equipment retrofits have, for the first time, separated construction growth from rising emissions by improving how resources are used. Cities like Oslo, Helsinki, London, and Amsterdam—part of the C40 network—combine resource efficiency with zero-emission mandates, with Oslo requiring fossil-free construction sites since 2019 and planning fully zero-emission public sites by 2025. The EU’s Stage V standards, in place since 2019, improve fuel use while reducing pollutants, prompting cities like London to tighten machinery rules. Meanwhile, the IEA and WorldGBC roadmap shows efficiency can cut embodied and operational emissions by 20 to 50 percent. In contrast, Australia focuses heavily on material and fuel changes, neglecting on-site fuel optimisation.

Australia’s Missed Opportunity

Reports from the Australia Institute and the Clean Energy Finance Corporation call for reforming subsidies and switching to alternative fuels, but they don’t link these incentives to efficiency upgrades, which could maximise their impact. Infrastructure NSW’s 2025 Roadmap prioritises low-carbon fuels and materials, yet overlooks the fuel savings possible with better engines that could enhance those efforts. The Heavy Vehicle Industry Australia supports improving fleet efficiency, but this focus hasn’t reached off-road construction equipment guidance. Federal plans, including the 2025 Transport Roadmap, address on-road and material emissions but leave out off-road diesel opportunities, risking an influx of outdated machinery.

Overcoming Barriers and Moving Forward

Some worry that upgrading equipment is too expensive, but the evidence suggests otherwise. Here’s how efficiency can work in practice:

- Cost-Effective Upgrades: The 20–35 percent fuel savings from modern engines can cover costs in 1 to 2 years, offering a strong financial incentive.

- Global Success Stories: Cities like Oslo and the EU’s Stage V adoption demonstrate how efficiency smooths the transition to low-carbon solutions.

- Actionable Steps: We recommend tying fuel tax credits to Stage V compliance, setting national machinery benchmarks, requiring better diesel usage reporting, and learning from C40 cities and GlobalABC with retrofits and zero-emission goals.

- Bridging to the Future: While electric technology is likely the endgame for decarbonisation of construction equipment, optimising fuel use now provides a critical interim step, reducing emissions and costs until electric solutions are fully scalable.

Policymakers and industry leaders must act now to make efficiency the foundation of our decarbonisation efforts. This approach will unlock cost savings, improve air quality, and accelerate our path to net zero.

Follow Mansfield Advisory Pty Ltd for more insights!

Further articles on transitioning to Fossil Fuel Free Construction can be found here.

REFERENCES

- Australian Taxation Office. (2025). Fuel Tax Credits Scheme Annual Report 2024–2025. Canberra: ATO.

- Department of the Treasury. (2024). Budget Paper No. 2: Budget Measures 2024–2025. Canberra: Australian Government.

- Infrastructure Australia. (2024). Embodied Carbon Projections for Australian Infrastructure and Buildings 2024. Sydney: Infrastructure Australia.

- Australian Government. (2024). Australian Petroleum Statistics 2023–2024. Canberra: Department of Industry, Science and Resources.

- Atlas Copco. (2023). Stage V Technical Guide: Engine Efficiency and Emissions. Nacka: Atlas Copco.

- UK Health and Safety Executive. (2023). Diesel Engine Exhaust Emissions in Construction: Health Risks. London: HSE.

- Safe Work Australia. (2024). Diesel Exhaust Exposure Guidelines. Canberra: Safe Work Australia.

- Greater London Authority. (2024). Non-Road Mobile Machinery Low Emission Zone Policy 2025–2040. London: GLA.

- Western Australia Department of Energy, Mines, Industry Regulation and Safety. (2023). Diesel Emissions Management Guidelines. Perth: DEMIRS.

- International Energy Agency. (2024). World Energy Outlook 2024; C40 Cities. (2024). Clean Construction Programme Report; World Green Building Council. (2024). Net Zero Carbon Buildings Roadmap. Paris/London: IEA/C40/WorldGBC.

- Australia Institute. (2024). Subsidies and Sustainability: Reforming Fuel Tax Credits; Clean Energy Finance Corporation. (2024). Decarbonizing Heavy Industry Report. Canberra/Sydney: Australia Institute/CEFC.

- Infrastructure NSW. (2025). Decarbonising Infrastructure Roadmap 2025. Sydney: Infrastructure NSW.

- Heavy Vehicle Industry Australia. (2024). Transition to Low-Emission Fleets: Policy Submission. Canberra: HVIA.

- Department of Infrastructure, Transport, Regional Development, Communications, and the Arts. (2025). Transport and Infrastructure Net Zero Roadmap and Action Plan 2025. Canberra: Australian Government.

- International Council on Clean Transportation. (2021). Efficiency Technology Potential for Heavy-Duty Vehicles. Washington, DC: ICCT.