Accelerating the Transition to Fossil Fuel-Free Construction

205 followers

May 27, 2025

By Jeremy Mansfield OAM, Mansfield Advisory Pty Ltd

Introduction

The construction industry accounts for 40% of global carbon emissions, with a significant portion stemming from onsite activities and embodied carbon in materials [1]. In Australia, where infrastructure and buildings are key economic drivers, the sector’s emissions—particularly from construction processes (A5 emissions)—present both a challenge and an opportunity. Fossil fuel-free construction, which eliminates fossil fuels from onsite energy, machinery, transportation, and materials, is a critical step toward net zero by 2050.

At Mansfield Advisory, we are committed to driving this transformation. Drawing on insights from ASBEC’s Our Upfront Opportunity report [1], Infrastructure Australia’s Embodied Carbon Projections for Australian Infrastructure and Buildings [2], the NABERS Embodied Carbon framework [3], and the C40 Clean Construction Accelerator, this article outlines the path to fossil fuel-free construction. It’s a call to action for government and industry to collaborate on policies and practices that will reshape how we build.

What is Fossil Fuel-Free Construction?

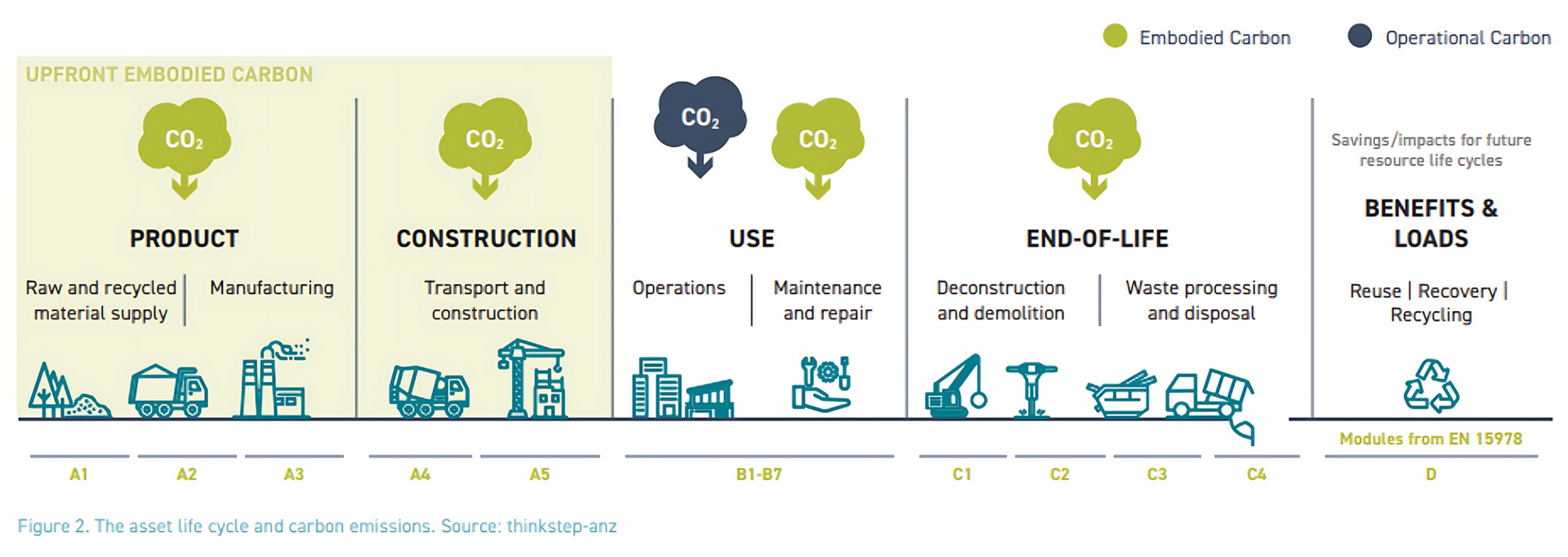

Fossil fuel-free construction eliminates fossil fuels across onsite activities (A5 emissions under EN15978), focusing on four key areas:

- Energy Sources: Powering construction sites with onsite or offsite renewable energy like solar, wind, or hydropower.

- Machinery: Using renewable electricity, low-carbon liquid fuels or renewable hydrogen to power machinery and equipment, instead of diesel, LPG or gasoline.

- Transportation: Deploying electric or low-carbon liquid fuel vehicles for moving materials and workers.

- Materials: Prioritising low-carbon options that minimise fossil fuel use in production.

Figure 2 diagram from ASBEC’s Our Upfront Opportunity report illustrating the EN15978 lifecycle stages, with A5 (construction process) highlighted.

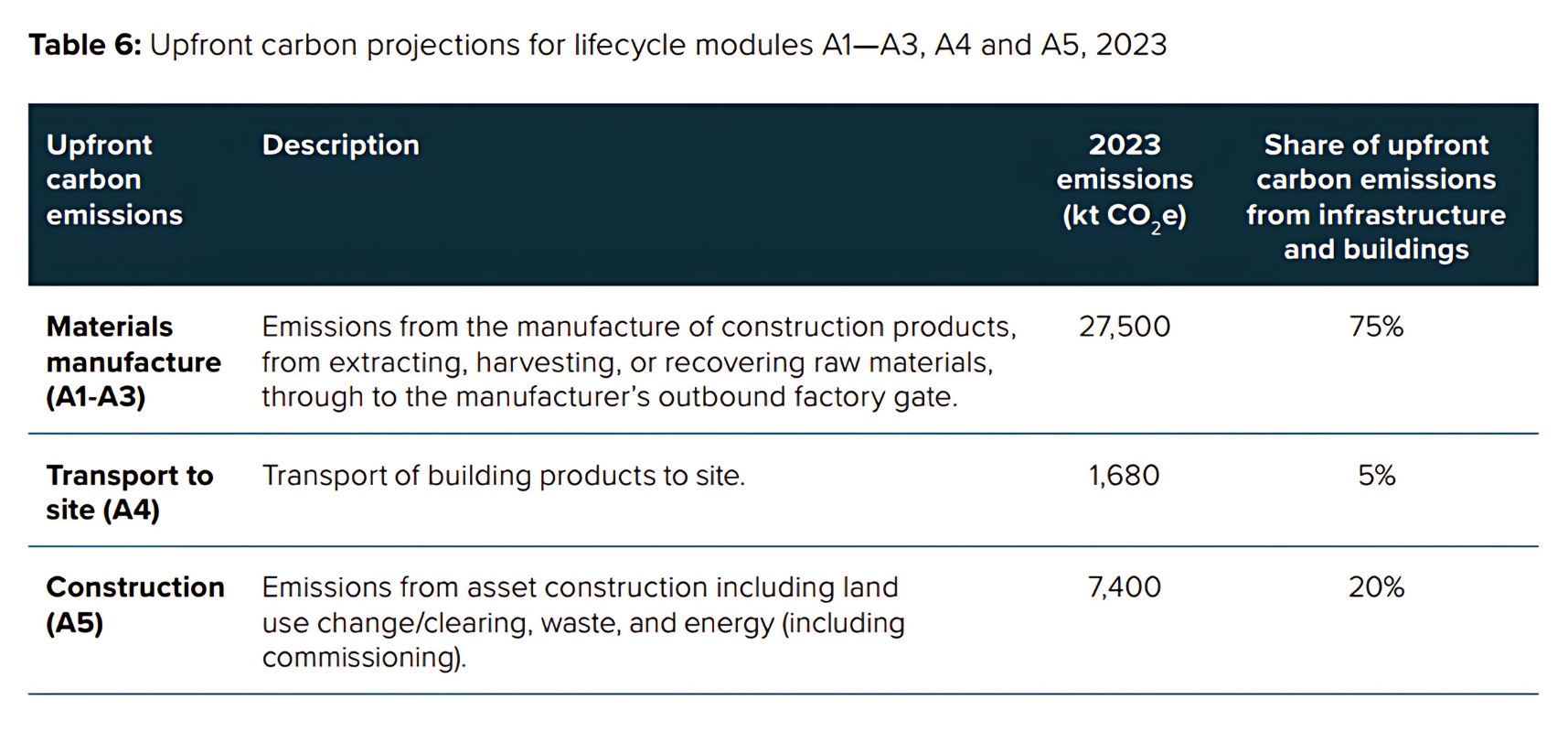

Infrastructure Australia’s Embodied Carbon Projections for Australian Infrastructure and Buildings and ASBEC have highlighted that Construction Emissions (A5) represent 20% of upfront carbon emissions from infrastructure and buildings. While it is essential to address the significant carbon emissions resulting from materials manufacture (A1-A3), which constitute 75% of upfront emissions, it is equally essential to consider construction-related emissions to achieve Australia’s net-zero targets by 2050 [1].

Table 6: Upfront carbon projections for lifecycle modules A1—A3, A4 and A5, 2023, Embodied Carbon Projections for Australian Infrastructure and Buildings 2024

Why It Matters

The stakes are high. Infrastructure Australia’s report warns that embodied carbon from construction could account for up to 85% of a project’s total emissions by 2050 if left unchecked [2]. Fossil fuel-free construction offers compelling benefits:

- Climate Impact: Cutting onsite emissions directly reduces a project’s carbon footprint.

- Public Health: Eliminating fossil fuel use improves air quality and reduces noise pollution.

- : Shifting to renewables enhances energy security and fosters innovation. Transition to electric and battery electric vehicles saves significant equipment fuel costs.

The NABERS Embodied Carbon tool supports this transition by providing a standardised way to measure and manage A5 emissions, ensuring accountability across projects [3]. It includes the energy use during the entire construction up to Practical Completion. Complete records of energy consumption must be obtained for all the following energy sources, if they were used on-site during the construction period: Diesel; BioDiesel, Renewable Diesel, Petrol, Electricity (grid), Off-site renewable electricity (i.e., GreenPower or other grid-sourced renewables), Natural gas, and LPG.

Barriers to Overcome

Despite its potential, fossil fuel-free construction faces hurdles:

- Cost and Technology: Electric machinery and renewable energy systems often require higher upfront investment.

- Cost of using imported fuels: No domestic refining for renewable diesel fully commercialised yet.

- Infrastructure Gaps: Many project sites lack access to renewable energy or charging stations.

- Supply Chain Complexity: Achieving fossil fuel-free outcomes requires coordination across all project phases.

- Limited Awareness of Electrification Options: Many construction stakeholders, including contractors and developers, lack awareness of available electrification technologies, such as battery-powered excavators, electric concrete pumps, and zero-emission transport vehicles, hindering their adoption and slowing the transition to fossil fuel-free construction.

- Insufficient Market Signals and Policy Support: The absence of clear and consistent market signals, such as firm commitments to decarbonisation targets, leaves suppliers uncertain about investing in low-carbon solutions like renewable fuels at large volumes and the electric equipment transition. Compounding this, current regulations rarely mandate or reward sustainable construction practices. No Australian city has committed to the C40 Clean Construction Accelerator—a global pledge by cities like Oslo, London, and Los Angeles to reduce fossil fuel emissions from construction sites through collaborative procurement and policy alignment, further slowing the transition.

These challenges are real, but they are not insurmountable with the right support.

Solutions and Policy Recommendations

To scale fossil fuel-free construction, Australia must act decisively, aligning with ASBEC's goal of fossil fuel-free construction by 2031 and a 60-75% reduction in upfront embodied carbon (A1-A5) by 2035, as outlined in the Our Upfront Opportunity report [1]. The C40 Clean Construction Accelerator provides a complementary global framework, with goals to reduce embodied emissions by 50% for new buildings, retrofits, and infrastructure by 2030, and require zero-emission construction sites by 2030 where technology is available. Here’s how Australia can accelerate the transition to fossil fuel-free construction while contributing to broader decarbonisation goals:

- Adopt Fossil Fuel Free Construction Hierarchy: (1) Use of electric construction machinery and equipment where options are available; and (2) Renewable diesel to substitute mineral diesel where electric options are not available (Lendlease hierarchy in their Stepping Up The Pace: Fossil Fuel Free Construction Report - 2022).

- Measure and Report Emissions: Mandate A5 emissions tracking using tools like NABERS Embodied Carbon to create transparency [3], supporting significant embodied carbon reductions.

- Fund the Transition: Offer grants, tax incentives, or subsidies to offset the cost of electric equipment and renewable energy and liquid fuel adoption, accelerating progress toward broader decarbonisation goals.

- Update Procurement: Embed fossil fuel-free requirements into public and private project tenders. State and Federal Governments, by utilising GBCA’s Green Star Buildings Fossil Fuel Free Construction Leadership Challenge, can incentivise and signal market transition.

- A Coordinated National Effort: ASBEC’s Our Upfront Opportunity report calls for the NCC to set clear, mandatory targets for upfront embodied carbon [1]. By embedding fossil fuel-free requirements within the scope of upfront embodied carbon provisions (aligned with NABERS Embodied Carbon A1-A5 boundary) into the NCC, Australia can drive industry-wide adoption of low-carbon materials and practices, aiming for fossil fuel-free construction by 2031.

- Build Infrastructure: Develop renewable energy microgrids and charging networks at construction hubs to enable fossil fuel-free practices.

- Train the Workforce: Equip workers with skills to operate new technologies through targeted programs, focusing on Fossil Fuel Free Construction, Retrofits, Low-Carbon Materials, and Zero-Emission Machinery, to support the transition.

- Pilot and Innovate: Support demonstration projects to prove the viability of fossil fuel-free construction methods and share results, accelerating adoption.

Leading by Example

Progress is underway both locally and globally, showing what’s possible with commitment and innovation.

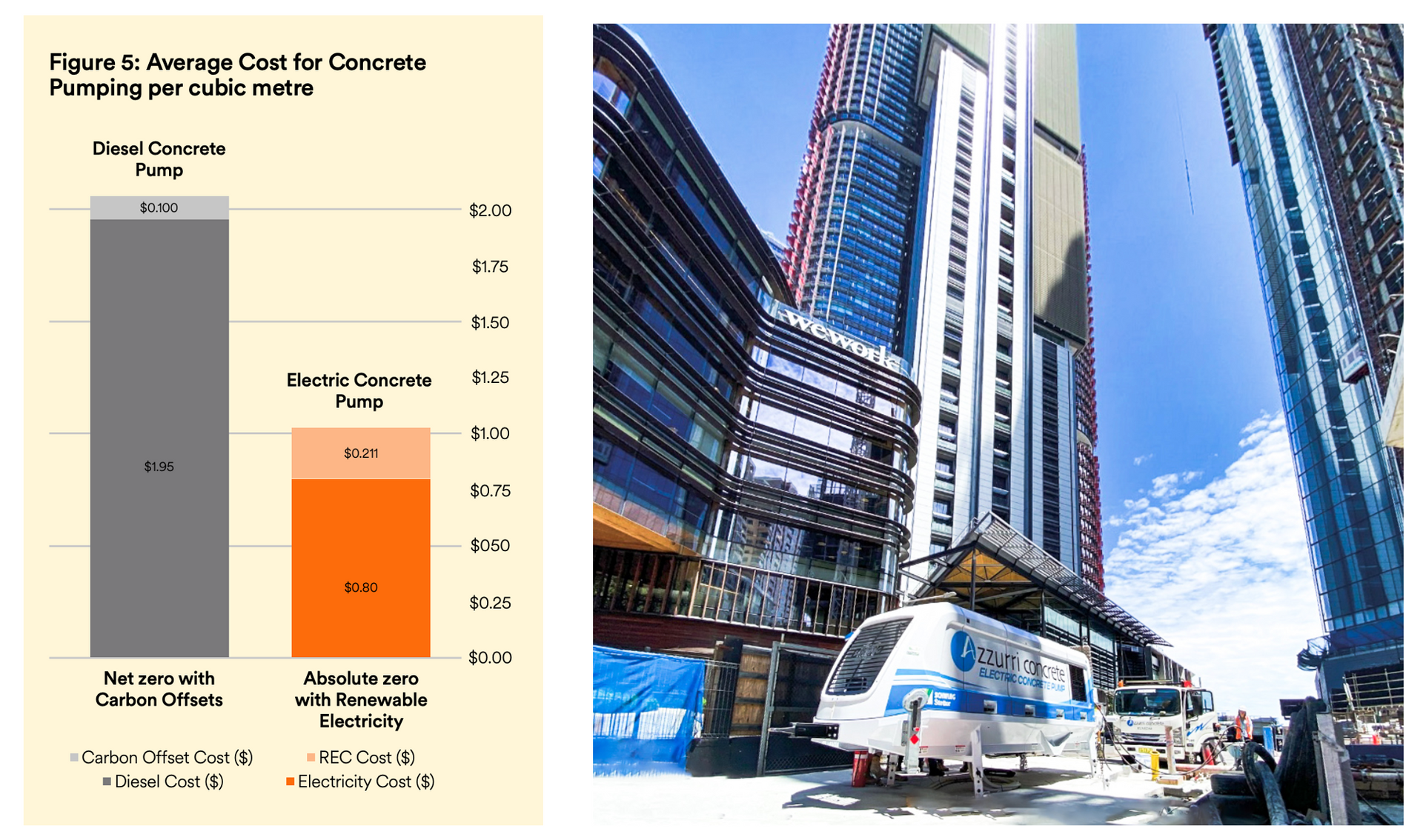

Australian Innovators

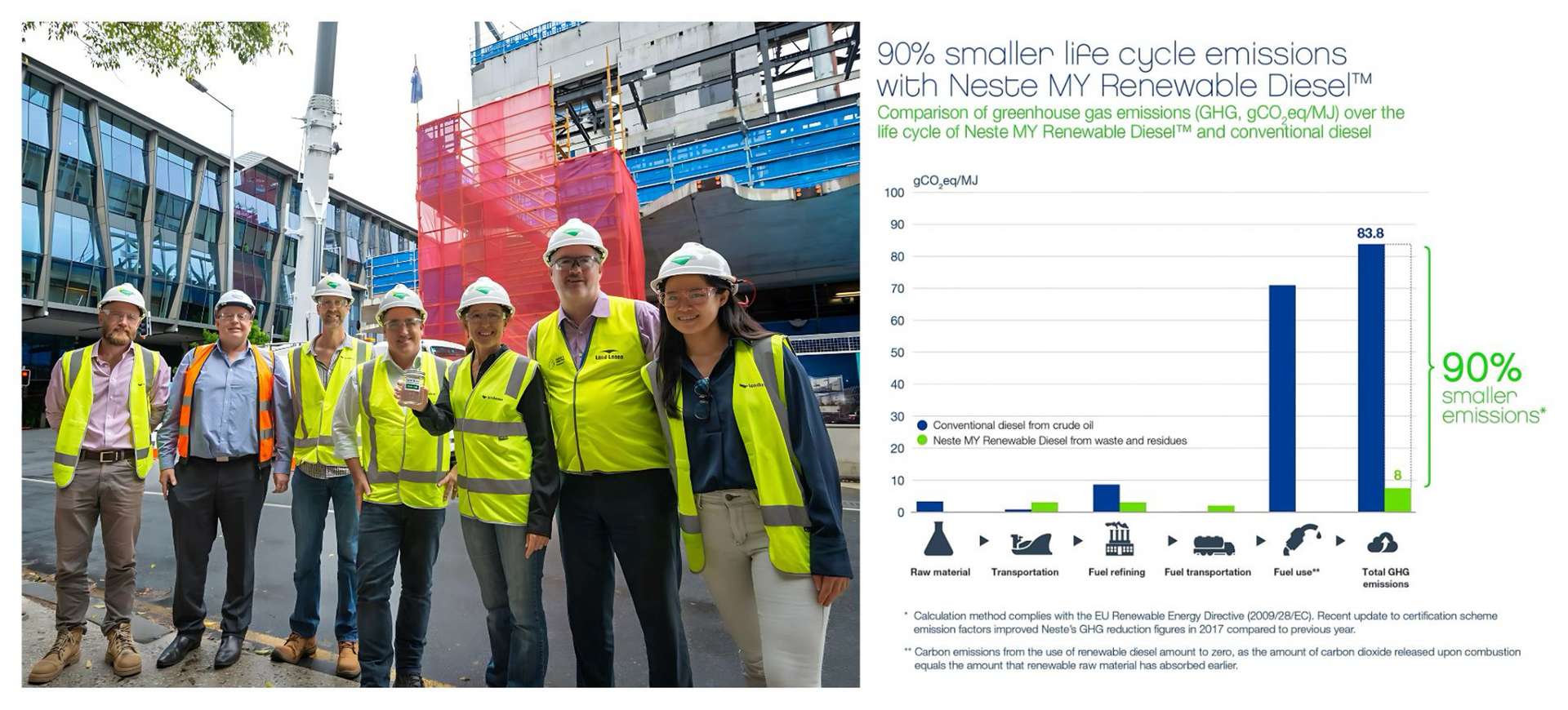

Lendlease, a pioneer in sustainable building, has trialled electric machinery, such as the Schwing SP 3800 E electric concrete pump supplied by Azzurri Concrete at the One Sydney Harbour project, achieving zero emissions and 59.1% lower operational energy costs [4]. They have also adopted renewable diesel, reducing emissions by up to 90% compared to traditional diesel [1]. The NSW Government’s focus on embodied carbon in infrastructure projects sets a strong example [5]. These efforts show that the tools exist—now we must scale them to drive fossil fuel-free construction and support broader decarbonisation goals.

A comparison of electric concrete pumping vs Diesel concrete pump. Source: Lendlease / Azzurri Concrete

A combined image of HVO (renewable diesel) being used at Lendlease’s New Performing Arts Venue project (Brisbane) with the Nestlé graph showing the percentage emissions reduction (up to 90% compared to diesel).

Suppliers Driving Change

Volvo Group is playing a pivotal role in decarbonising transport and construction equipment, supporting the industry’s transition to fossil fuel-free practices. From December 2024, all Volvo and Mack trucks built at Volvo Group Australia’s Wacol QLD factory have been filled with Hydro Treated Vegetable Oil (HVO) instead of diesel—a renewable fuel that reduces emissions by up to 90% when sourced sustainably. Volvo aims to make its trucks and construction equipment fossil fuel-free by 2040, a timeline that lags behind ASBEC's goal of fossil fuel-free construction by 2031, underscoring the need for accelerated action.

Volvo Trucks and Volvo Construction Equipment (CE) are heavily investing in electrification, with electric trucks enabling low-emission material transport for construction projects. Volvo CE’s range of electric equipment, tailored for construction and landscaping, includes the 23-ton EC230 Electric mid-size excavator, L120 Electric and L90 Electric wheel loaders, the EWR150 Electric (Volvo’s first battery-powered wheeled excavator), and the grid-connected EW240 Electric Material Handler, which may face challenges in remote sites without renewable energy access.

EC230 Electric mid-size excavator. Source: Volvo Group

Other suppliers in the transport industry are also transitioning to electric solutions. Fuso, part of the Daimler Truck Group worldwide, has a rich history in Australia dating back to the 1970s. In 2021, they introduced the eCanter—the first production electric truck in Australia—gaining traction with leading transport operators like Australia Post. International suppliers like JAC are also entering the market with their electric truck offerings, expanding options for zero-emission transport. Electric trucks offer lower maintenance requirements compared to diesel counterparts, with fewer moving parts and no need for oil changes or exhaust system repairs. Additionally, electricity as a fuel source is generally cheaper than diesel, reducing operational costs over time. With a payback period of 3 to 4 years, the economic case for electrification is compelling. However, only a handful of electric truck models are currently available in Australia, reflecting the market’s slower uptake compared to Europe, Asia, and the U.S. A stronger focus on supplying the decarbonization needs of Australia’s built environment and infrastructure sectors could accelerate interest from suppliers, supporting the Fossil Fuel Free Construction agenda.

Fuso eCanter, Australia’s first production electric truck, arrived in 2021. Source:

Government leadership

The NSW Decarbonising Infrastructure Delivery Policy has set mandatory requirements for agencies to apply the Carbon Reduction Hierarchy when identifying potential opportunities to reduce carbon. The Carbon Reduction Hierarchy has been adopted from PAS 2080: 2023 – Carbon Management in infrastructure.

The NSW Decarbonising Infrastructure fact sheet ( How to reduce carbon on your project?) provides good examples of the signals the industry needs to switch to low-carbon options, materials, and technologies whilst adopting solutions that improve resource efficiency and circular economy outcomes. Acknowledging the need to switch to low-carbon fuels and energy systems, along with adopting low-carbon construction methods.

It is critically important when engaging with the market that the right signals are embedded in business cases. Articulating fossil fuel-free construction targets (for A5 carbon emissions) is absolutely critical. Product suppliers rely on clear forward projection of the demands for their low-carbon options, materials and technologies. For example, without securing a large supply order for the use of renewable fuels, how does the supply industry invest the capital with the confidence that there's adequate demand for their low-carbon solutions? It's not a question of asking the industry what their ability to supply is; it's a matter of setting targets that the industry can signal to the suppliers the need for capacity to meet those targets.

Global Leaders in Fossil Fuel-Free Construction

Globally, cities are setting the standard for fossil fuel-free construction through the C40 Clean Construction Accelerator, which includes signatories like Budapest, Los Angeles, London, New York City, Mexico City, Milan, Oslo, and San Francisco:

- Oslo, Norway: Oslo is targeting a 95% emissions reduction by 2030, mandating zero-emission heating and drying equipment for projects worth 5 million euros or more, with bonuses for contractors using additional zero-emission machinery. Its procurement strategy prioritises environmental criteria (30% weighting, 50% for zero-emission Non-Road Mobile Machinery), driving market change that aligns with global efforts to decarbonise construction.

- London, United Kingdom: London is committed to reducing embodied emissions, requiring life-cycle assessments (LCAs) in planning permissions and promoting zero-emission machinery in municipal projects, aligning with C40 goals that support broader decarbonization efforts.

- Los Angeles, USA: Los Angeles is leveraging its municipal procurement power to demand zero-emission construction sites, focusing on circular design and low-carbon materials, offering strategies Australia can adopt to advance fossil fuel-free practices and reduce embodied carbon.

- Milan, Italy: Milan is prioritising retrofits of existing buildings and advocating for low-carbon materials, supporting the C40 goal of a 50% reduction in embodied emissions by 2030, which provides a benchmark for Australia’s decarbonisation efforts.

- Supplier Spotlight: Tom Wilhelmsen AS (Norway): Norwegian supplier Tom Wilhelmsen AS exemplifies how suppliers can advance fossil fuel-free construction by adopting electric trucks for sustainable material transport. The company operates a fleet of 19 trucks, including 10 small intercity long-distance Volvo FE Electric tipper trucks without trailers, each capable of carrying 13.5 tonnes, used for construction operations. Since 2020, Tom Wilhelmsen AS has expanded its electric fleet in response to growing demand for sustainably sourced materials, aligning with Oslo’s zero-emission goals. This demonstrates how clear market signals can drive supplier investment in low-carbon solutions, offering a model for Australian suppliers to support the transition to fossil fuel-free construction.

These global examples of city-led policies and supplier leadership demonstrate practical steps toward fossil fuel-free construction, providing a blueprint for Australia to accelerate its pursuit of fossil fuel-free construction by 2031.

Oslo has a zero-emission construction mandate. Source: City of Oslo.

The Power of Consistent Data: Reporting Emissions Accurately

Accurate emissions reporting is critical to driving progress. The NABERS Embodied Carbon framework aligns with operational control boundaries, ensuring that construction companies report emissions from activities they directly manage. This alignment, as per the National Greenhouse and Energy Reporting (NGER) scheme, places accountability on those best positioned to reduce onsite emissions (A5 emissions) [3].

However, a significant gap exists in quantifying diesel consumption in construction, with estimates ranging from 1–4 billion litres annually due to inconsistent reporting [6]. This uncertainty hinders our ability to fully understand A5 emissions and prioritise fossil fuel-free solutions. To tackle reporting challenges, construction companies must advocate for:

- Policymakers and industry bodies to mandate that clients, who often control utility payments, share consumption data with contractors. The industry should also ensure supply chains adopt consistent reporting on onsite fuel and energy use to track A5 emissions and promote low-carbon solutions, such as electric trucks.

- Standardised reporting templates to streamline reporting and reduce complexity. We cannot afford hundreds of different templates—consistency is key.

Discrepancies also arise when financial control boundaries are used, as permitted under standards like the Australian Sustainability Reporting Standards (ASRS) and the GHG Protocol. These boundaries can create gaps, underrepresenting A5 emissions and obscuring the actual emissions intensity of construction projects. By aligning reporting frameworks, closing the diesel consumption data gap, and fostering collaboration, we can ensure clarity and accountability, supporting the transition to fossil fuel-free construction.

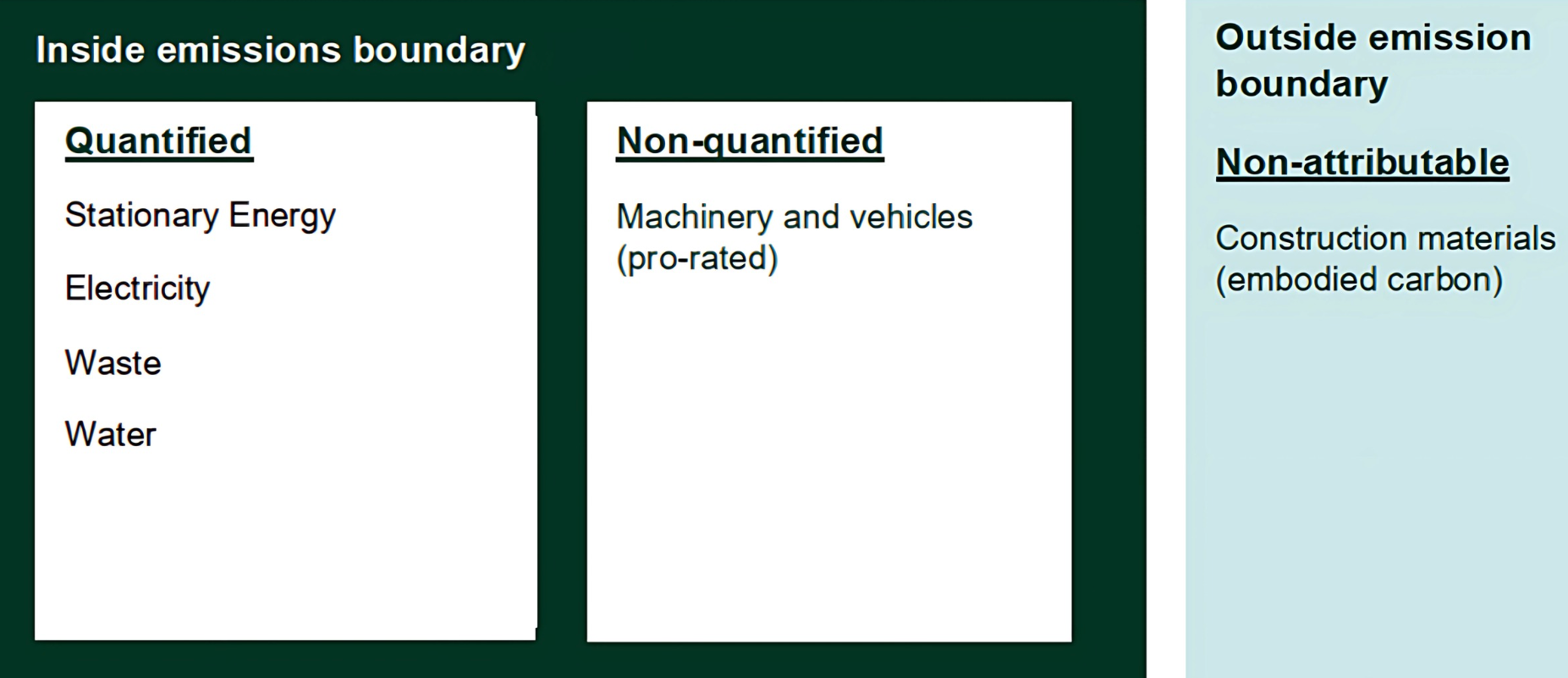

An extract from Climate Active Carbon Neutral Construction Service Public Disclosure Statement outlining the emissions boundary, which is aligned with A5 emissions and NGER operational control boundaries. In contrast, a Financial Control boundary only includes items where the Contractor pays for the consumption. Source: Lendlease Construction (Aust) Holdings Pty Limited – Climate Active PDS (2024).

Conclusion

Fossil fuel-free construction is both an urgent necessity and a transformative opportunity. By aligning with ASBEC’s vision to decarbonise the built environment, drawing on data from Infrastructure Australia and NABERS, and learning from global leaders like Oslo, London, and Los Angeles, Australia can lead the way in sustainable construction. Mansfield Advisory is proud to drive this effort, providing expertise to make fossil fuel-free construction the standard.

Call to Action:

- Policymakers: Introduce incentives and mandates to support fossil fuel-free projects, and encourage Australian cities to join the C40 Clean Construction Accelerator to accelerate the transition.

- Industry: Commit to pilot projects, push for improved reporting standards, and adopt global best practices to advance the Fossil Fuel Free Construction agenda.

- You: Reach out to Mansfield Advisory to explore how we can collaborate on building a more sustainable future together.

The emissions we lock in today will shape tomorrow. Let’s take action now to achieve a fully fossil fuel-free construction sector.

References

- ASBEC. Our Upfront Opportunity: Australia’s Policy Roadmap to Reduce Upfront Embodied Carbon in the Built Environment. March 2025.

- Infrastructure Australia. Embodied Carbon Projections for Australian Infrastructure and Buildings. 2024.

- NABERS. Embodied Carbon Measurement Methodology and Tool. 2021.

- Lendlease. The Electric Edge of Concrete Pumping at One Sydney Harbour. February 2024. https://www.lendlease.com/insights/the-electric-edge-of-concrete-pumping-at-one-sydney-harbour/.

- NSW Government. Embodied Carbon in Infrastructure. 2024.

- Industry Discussions. Uncertainty in Diesel Consumption Estimates for Australian Construction. 2025.

First published on LinkedIn 27th May 2025